Product Instruction

Product Name : UV Coating Liquid,UV Coating Fluid,UV Coating Solution,UV Pretreatment Solution

Ink Type : Coating Fluid

Applicable Ink Type : LED UV Ink,UV Curable Ink

Colors: Colourless,Transparent

Smell : Slightly

Bottle Volume : 250ml / 500ml / 1000ml

Shelf Life : 18 Months

Feature : Super Adhesion,Beautiful Glossy,Fast Drying

Note : This product can not be diluted, please use directly

250ml UV Coating Liquid

500ml UV Coating Liquid

1000ml UV Coating Liquid

Product Details

With sealing film sealing, prevent ink leakage.

What Exactly is UV Coating?

By using gun spraying, dipping, roller coating, and brushing method, users can spray this pre-coating evenly on the surface of glass, where a layer of colorless coating film will be formed.

Then Led UV inks can be printed on the coating directly, which will add ink adhesion, and make the finished products waterproof, anti-climate, anti-scratch, and fadeless.

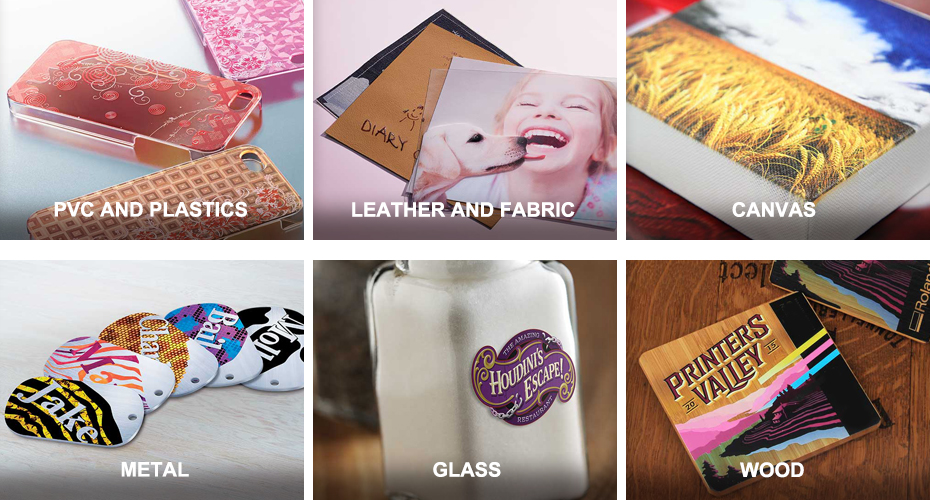

Applicable Material

Flexible material : wall paper,leather,film,canvas,polyethylene and etc.

Rigid material : acrylic,KT board,composite board,phone case,metal,ceramic,glass,stainless steel,aluminium alloy,plastic,silica gel,crystal,PVC,PET and etc.

Core Benefits of UV Coating

- Sustainability - Since these coatings contain no volatile organic compounds they are safe for a wide variety of applications.

- Speed - UV coating cures almost instantaneously,there is no need to dedicate time to drying.

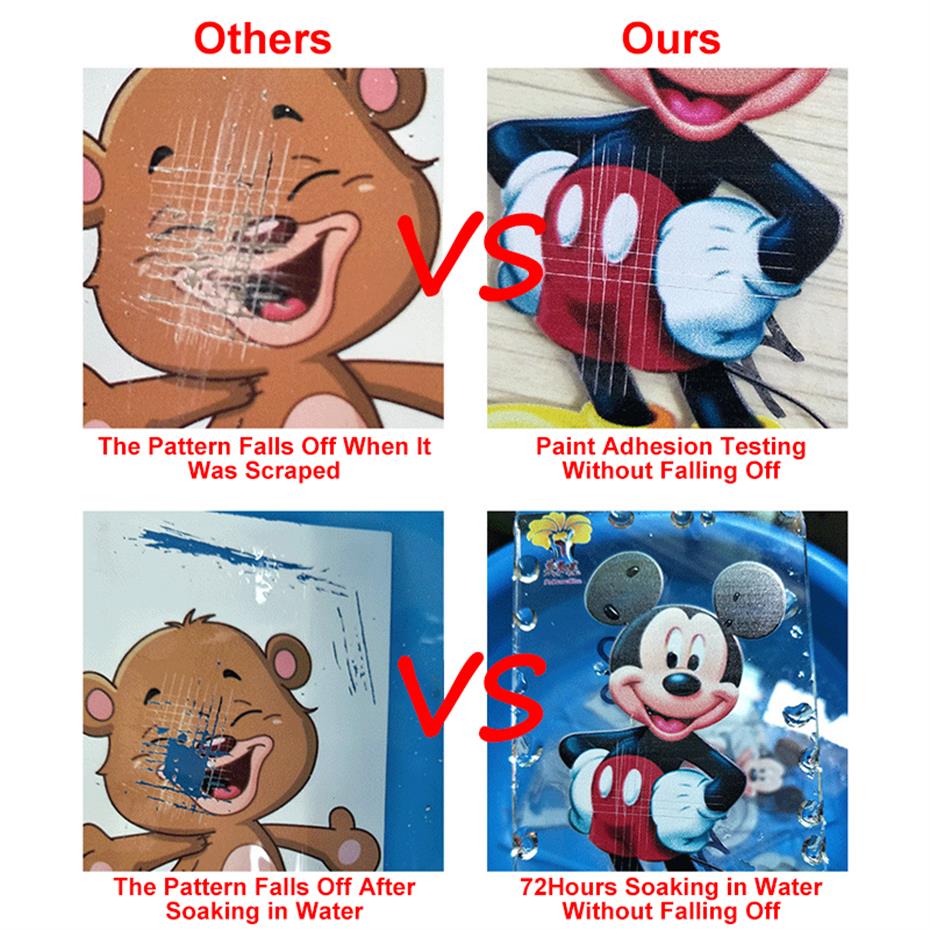

- Super Adhesion - Enhances adhesion between ink and print surface,make the ink adhere to the printing surface better.

- Protection - The coating helps resist abrasions, scratches, rubbing and ink smudging.

- Performance - UV coating offers a beautiful glossy sheen,the coating also smooth to the touch, it offers a pleasant tactile experience.

The prints which use this coating will not crack and fault when curved or folded, and have long outdoor warranty, waterproof, anti-climate, anti-scratch, and fadeless characteristics.

How to Use the UV Coating?

1.Clean the print surface with a clean cloth before printing,then spray the coating evenly on the printed surface with a spray gun.

2. After spraying,put it in the oven and bake at 100-150 degrees for 15-30 minutes.(The baking time and temperature depend on the material you print)

3.After drying,start printing.